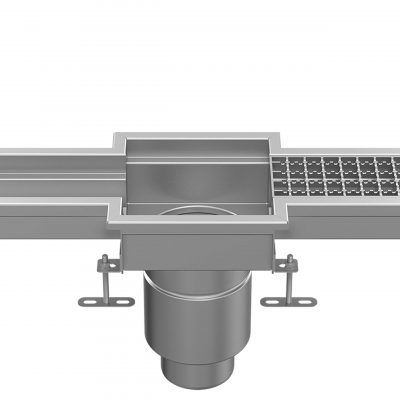

Rodding Eyes

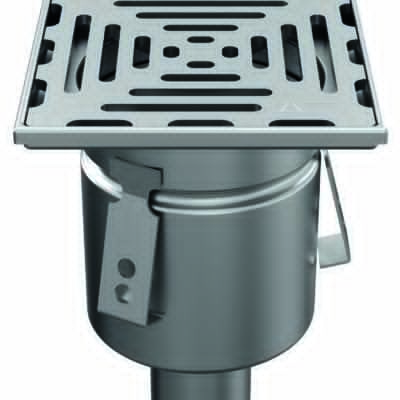

These sewage system elements are widely applied in industrial facilities (chemical, food, pharmaceutical plants etc.). Use of a rodding eye allows quick access to the underfloor area and easy cleaning. Rodding eyes are made of AISI304 or AISI316 grade steel. Penetration of water is prevented by the seal installed between the bolted cover and the body.

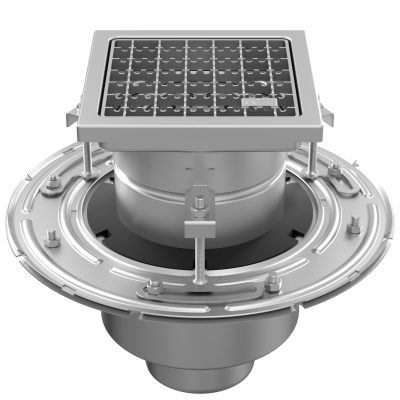

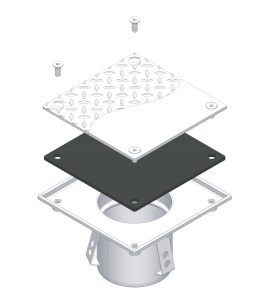

Two types of covers are available:

– smooth (G),

– checker plate (R).

Edge finish allows for installation in any type of floor.

We offer rodding eyes for sewage pipes of diameters from DN110.

ADVANTAGES OF RODDING EYES

– resistant to corrosion,

– provide a barrier against odours,

– easy installation,

– dimensions of offered rodding eyes are adapted to the sewage system diameter,

– an aesthetically pleasing design element.

INSTALLATION OF RODDING EYES

1. Drain pipe must be connected at an appropriate height.

2. While pouring concrete, the upper part of the rodding eye must be located approximately 1-1.5 [mm] below the floor.

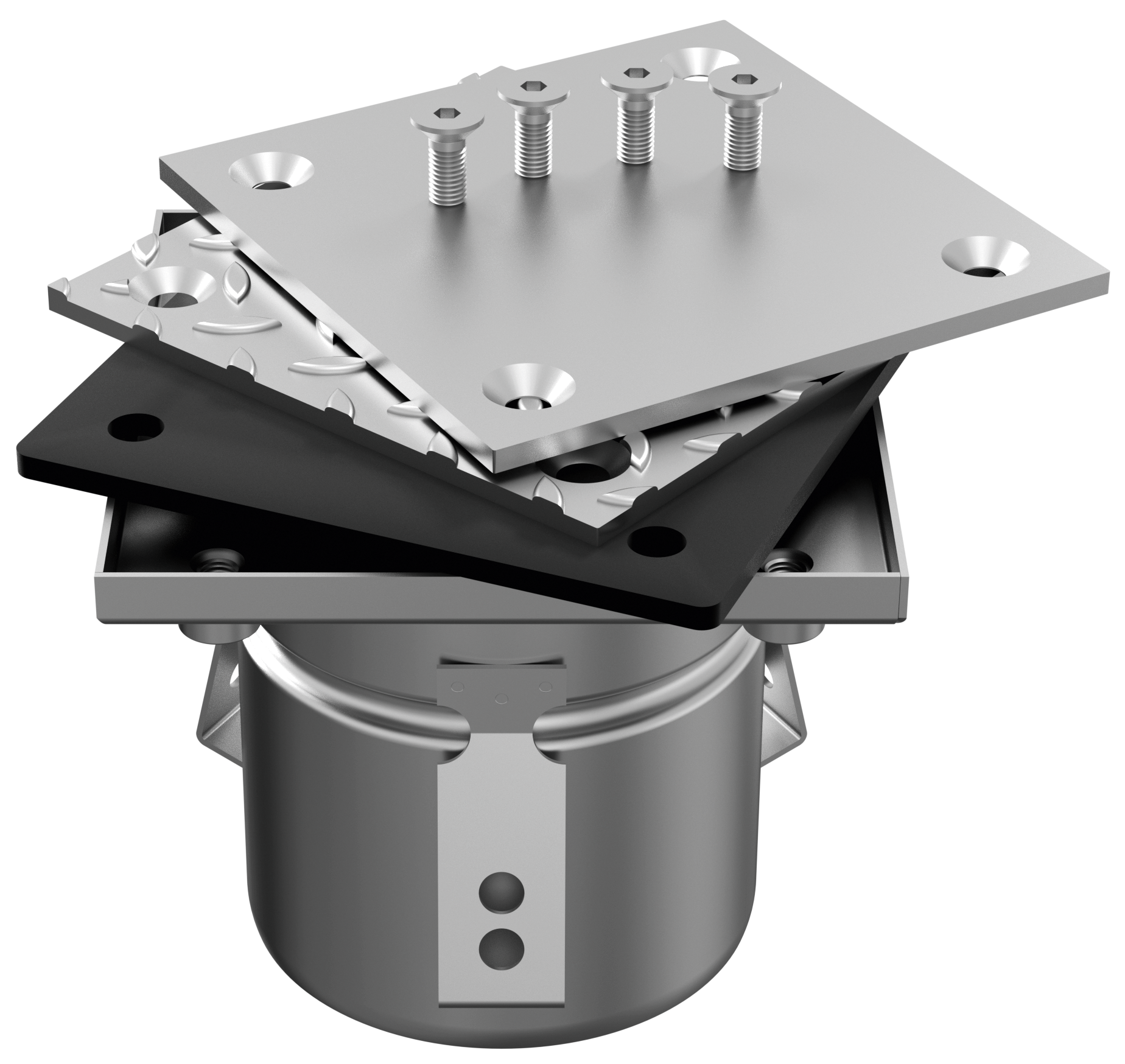

ELEMENTS OF RODDING EYE

– body,

– cover,

– fixing screws,

– seal.

- drain diameter from DN110 to DN200

- grates: smooth and checker

- a gasket installed between the screwed cover and the body prevents the ingress of water

- they are a barrier against unpleasant odors

- easy to assemble

- the size of the revisions offered has been adapted to the sewer diameter

- they are an aesthetic architectural element