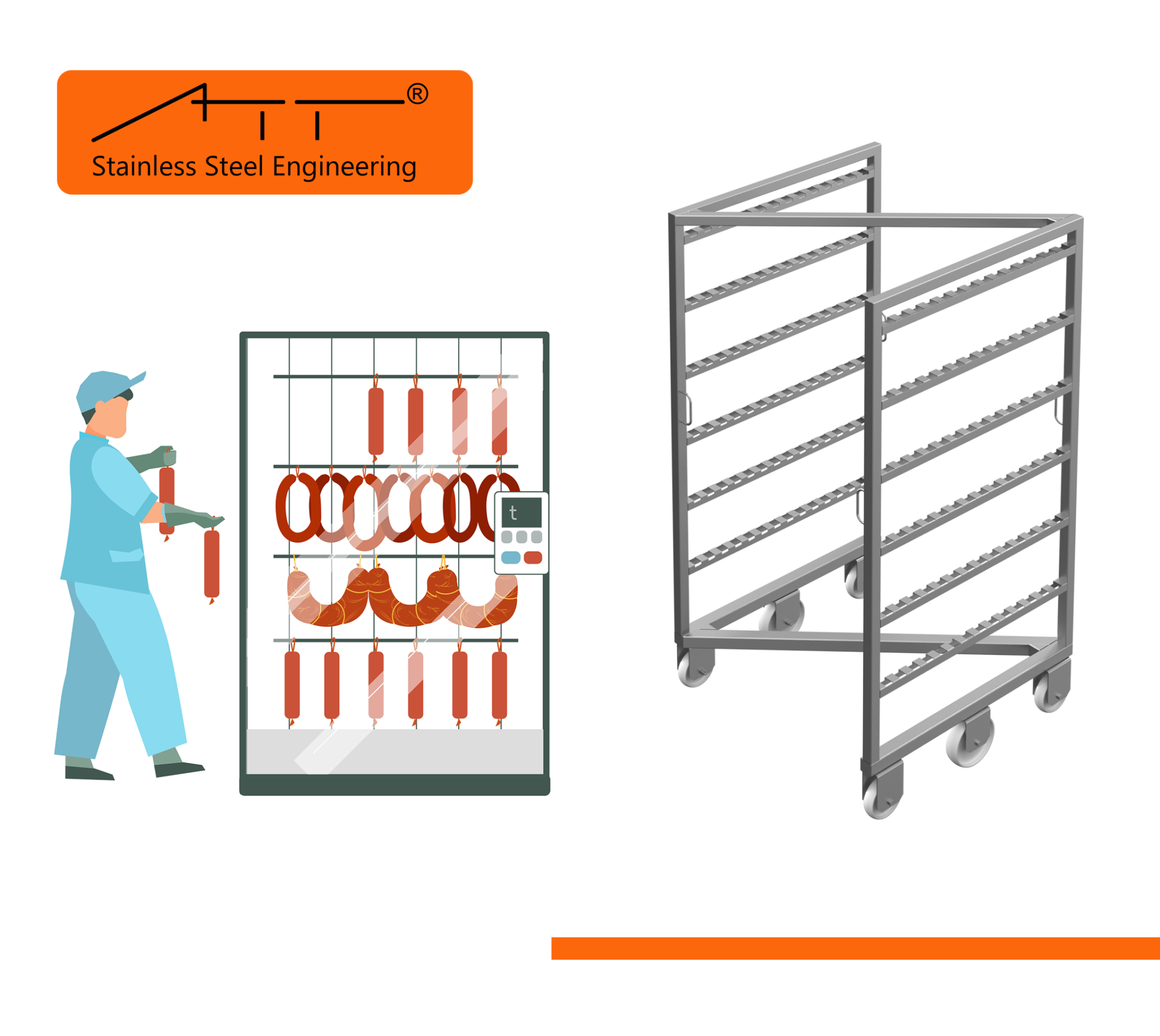

Smoking is a food technological process that involves preserving food using smoke. It gives food new flavor qualities and extends its shelf life. Smoking depends on several factors: the type of wood, process temperature, burning rate, and parameters of smoke distribution in the smoking chamber.

The increasing ecological awareness and specialized knowledge of the smoking process, combined with the use of the latest technologies, allow this process to be conducted in a way that meets the strict requirements of standards appropriate for food processing. Currently, smoking is carried out in specialized smoking chambers, where with the help of automation systems, we can control its parameters to obtain a product of the highest quality and safety for consumption.

A crucial element of equipment in the smoking process is the smoke trolleys made of stainless steel. It facilitates transport between successive stages of processing. The cart’s construction is universal and allows for the ergonomic arrangement of smoked products in a way that enables the extraction of the most favorable flavor qualities.

ATT smoking carts are made of stainless steel grade 304L (there is also a possibility of using material 316L). Standard carts are made in “Z construction” and “H construction”. These designs are optimized for storing a large  number of carts in a small space. Comparing both versions: Type Z, due to its less stable construction, is recommended for smoking lighter loads. Upon request, we also manufacture smoking carts with non-standard construction tailored to the client’s process requirements.

number of carts in a small space. Comparing both versions: Type Z, due to its less stable construction, is recommended for smoking lighter loads. Upon request, we also manufacture smoking carts with non-standard construction tailored to the client’s process requirements.

Advantages of ATT smoke trolleys made of stainless steel:

- biologically inert material – safe for food

- corrosion resistance – a key factor for safety in food processing processes

- easy to clean and resistant to cleaning agents used in washing processes in food processing plants

- resistance to temperature differences occurring in food processing processes

- product adapted for the use of rods and trays.

Additional equipment that can improve intra-plant transport, produced by ATT:

- ATT stuffing trolleys/euro bins.

Available capacities are 200 and 300 liters. They are used in food processing plants to transport semi-finished products.  The construction of these carts, compliant with DIN9797, is compatible with most loading systems commonly referred to as dumpers. Also importantly, it is a hygienic design. Compared to the competition, the cart has larger bottom and corner radiuses. This design prevents the filling from sticking in these places and facilitates the subsequent cleaning process.

The construction of these carts, compliant with DIN9797, is compatible with most loading systems commonly referred to as dumpers. Also importantly, it is a hygienic design. Compared to the competition, the cart has larger bottom and corner radiuses. This design prevents the filling from sticking in these places and facilitates the subsequent cleaning process.

- ATT transport trolleys.

This is another essential element of equipment in modern food production plants. Rollers support logistics operations by facilitating the transport of EURO containers (E1, E2, E3). The mobile construction allows tilting of the cart, facilitating maneuvering in tight spaces.

ATT – a leader in delivering stainless steel solutions.

ATT is one of the leading suppliers of stainless steel solutions for the food industry. For more than two decades, our company has been supplying innovative and high-quality products on nearly all continents.

- Quality – We place great attention on the quality of our products, ensuring the reliability, durability of stainless steel products.

- Innovation – Continuous investment in research and development, creating modern solutions tailored to the needs of the food industry.

- Adaptation to customer requirements – Adjustment to individual customer needs, allowing for optimal use of smoking carts in a given company.

- Technical suport – Assistance and advice in selecting appropriate solutions, allowing customers to maximize the potential of their equipment.

Następny

Następny